Manufacturing & Process Industries

Responsible for 10% of the UK’s total carbon emissions (2021)

Streamlining traditional processes

“We cannot become what we want to be by remaining what we are.” – Max DePree, Herman Miller

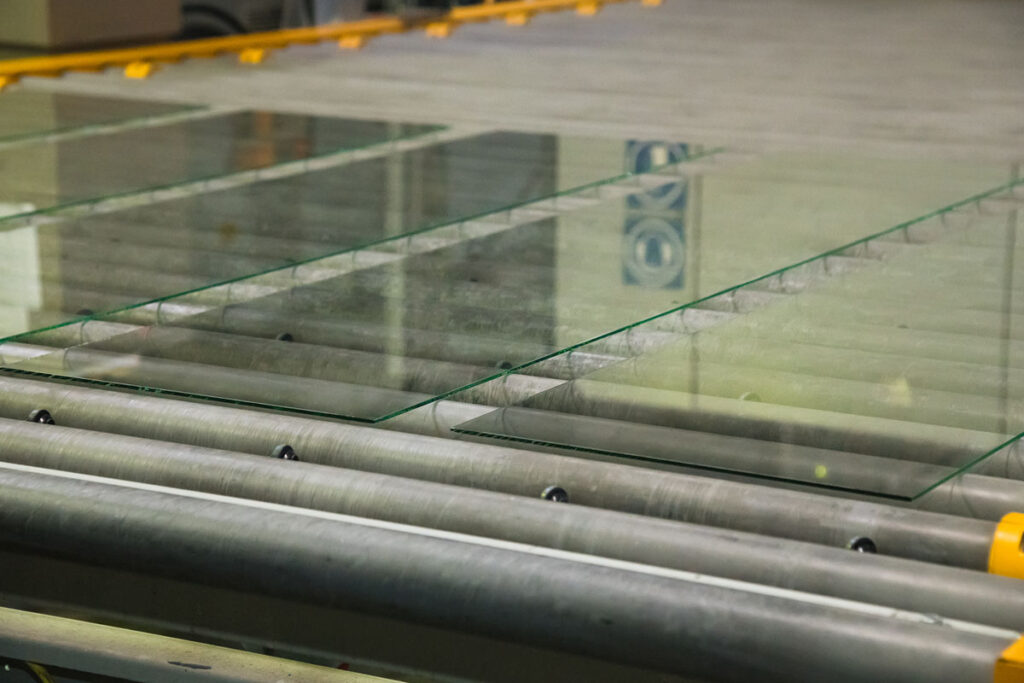

Traditional industries such as Metals, Glass, Ceramics, Paper, Cement, and Bulk Chemicals, have processes little changed since the Industrial Revolution.

These processes are complex and slow to adapt to the change required to bring about energy efficiencies required to meet their contribution to the Government’s net-zero target.

Traditional industries use a great deal of energy during production, and all of the processes are prone to incurring defects within the final products, which historically cannot be detected until the material is in its final and completed phases. As such, testing methods are usually destructive, resulting in unnecessary waste, and where defects are found, require a significant amount of energy to reprocess the material. Currently, the so-called ‘Foundation Industries’: Metal, Glass, Paper, Ceramics, Cement, and Bulk Chemicals, are responsible for 10% of the UK’s total carbon emissions. These industries also have challenges to overcome when it comes to changing processes and, historically, have been slow to adapt to and incorporate new technologies.

i3D is at the forefront of designing intelligent vision systems. These systems, incorporating stereo vision cameras, stereo matching algorithms, and machine learning, are not just theoretical concepts. They are practical solutions that can identify, characterise, and position defects in materials within a 3D context during the manufacturing process, offering tangible path efficiency and reduced carbon emissions towards energy.

With funding through Innovate UK, the UK’s national innovation agency, i3D is pioneering the development of intelligent vision systems. These systems have the potential to revolutionise traditional industries by enabling defect detection without the requirement for destructive testing methods and prior to the materials requiring intensive energy input for reworking. This transformative technology can streamline operations, reduce waste, lower energy input requirements, and significantly cut carbon emissions, offering a brighter, more sustainable future for these industries.