Project Description

i3D robotics has developed multiple inspection systems for decommissioning purposes either directly for Sellafield or the Nuclear Decommissioning Authority (NDA) and has worked with customers Jacobs, UK Atomic Energy Authority (UKAEA), and the National Nuclear Laboratory (NNL) to demonstrate these technologies.

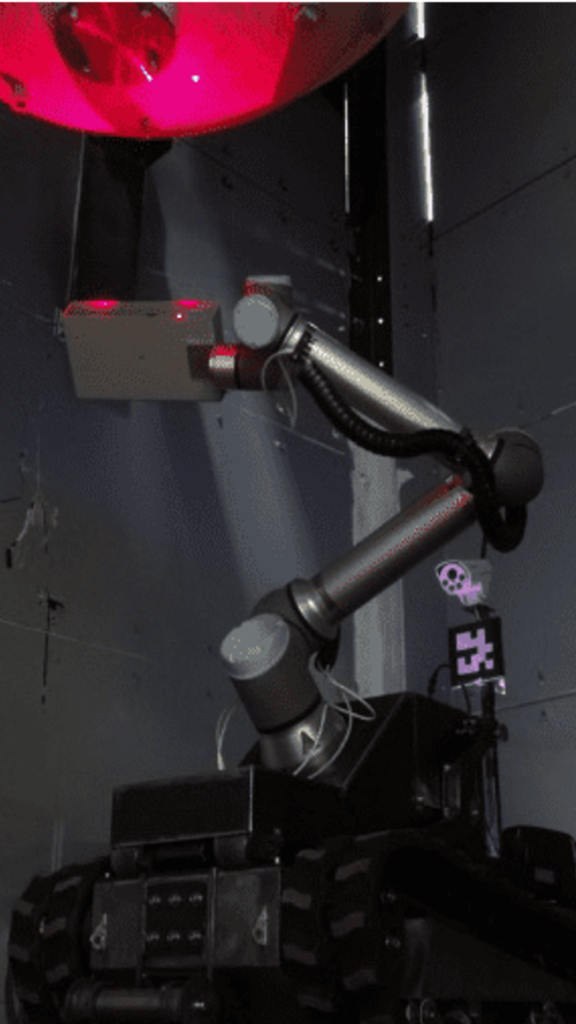

Bespoke Phobos 3D camera mounted on a UC-10 and DCE Marionette robot for mapping the interior of a glovebox during decommissioning

Client Challenge:

In 2017, the NDA and Innovate-UK launched a search for innovative technologies that could be combined into a seamless process for decommissioning critical parts of the UK’s legacy nuclear sites.

UK nuclear decommissioning site owner Sellafield Sites Limited requires remote inspection of unknown and potentially radioactive building structures, a legacy of the original atomic facility. The Thermal Oxide Reprocessing Plant (ThORP) must be cleared of their contents and decommissioned. There are scores of rooms, or ‘cells’, at the facilities requiring clearing, with the waste safely treated for packing and storage. First, an accurate assessment of the internal structure and infrastructure location, such as pipework and fittings, must be clearly understood. The conventional approach to working in this high-hazard environment involves teams of workers clad in protective air-fed suits entering the unit to investigate the contents. These workers would be restricted to working in the environment for no more than a few hours at a time due to the radioactivity. Lighting is usually poor, and hazards are unknown, so the process is highly time-consuming and costly and poses risks to the operators.

Inspection System Development:

We aimed to develop a modular integrated platform combining state-of-the-art technology with tried and tested decommissioning ‘know-how’, to produce a streamlined, safety-orientated solution. The system development used our experience of the pragmatic integration of complex technology to generate a step-change in decommissioning performance. i3Dr’s Phobos is designed to be compatible with robotics and automation systems and stand-alone mounting.

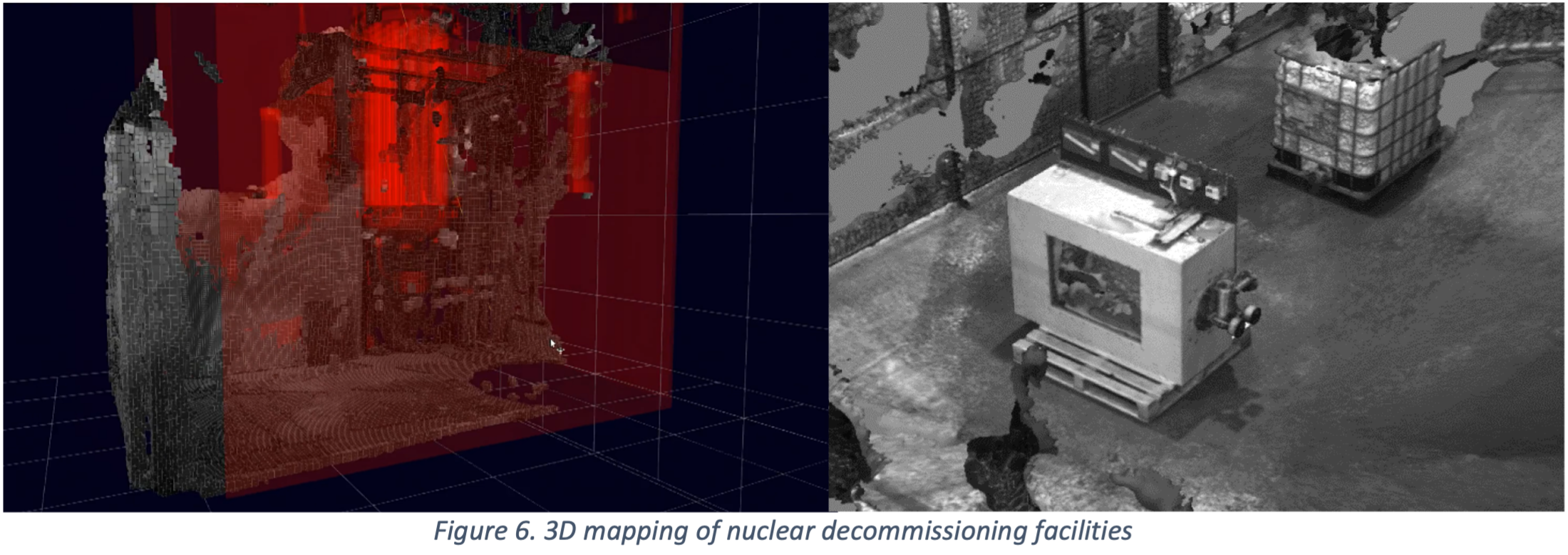

Our solution was to use a modified version of Phobos to deliver remote mapping capabilities at the scale required—this required integration with robotic platforms from Universal Robot and Digital Concepts Engineering.

Demonstration & further development:

“We were all incredibly excited by the quality and diversity of the submissions, which came from established nuclear organisations as well as industries working with us for the first time – such as space and defence sectors.” Melanie Bowbridge, Head of Technology, NDA

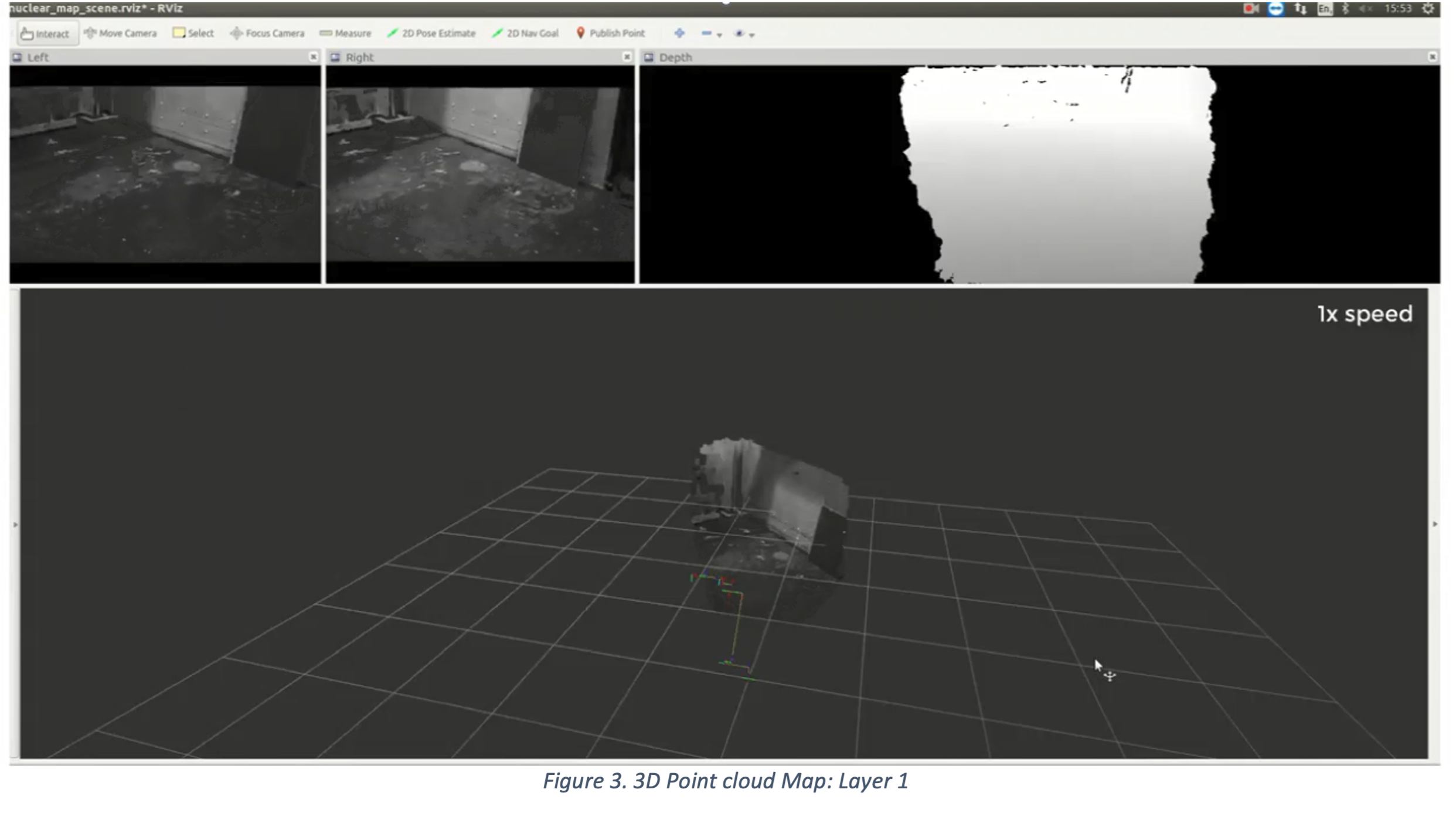

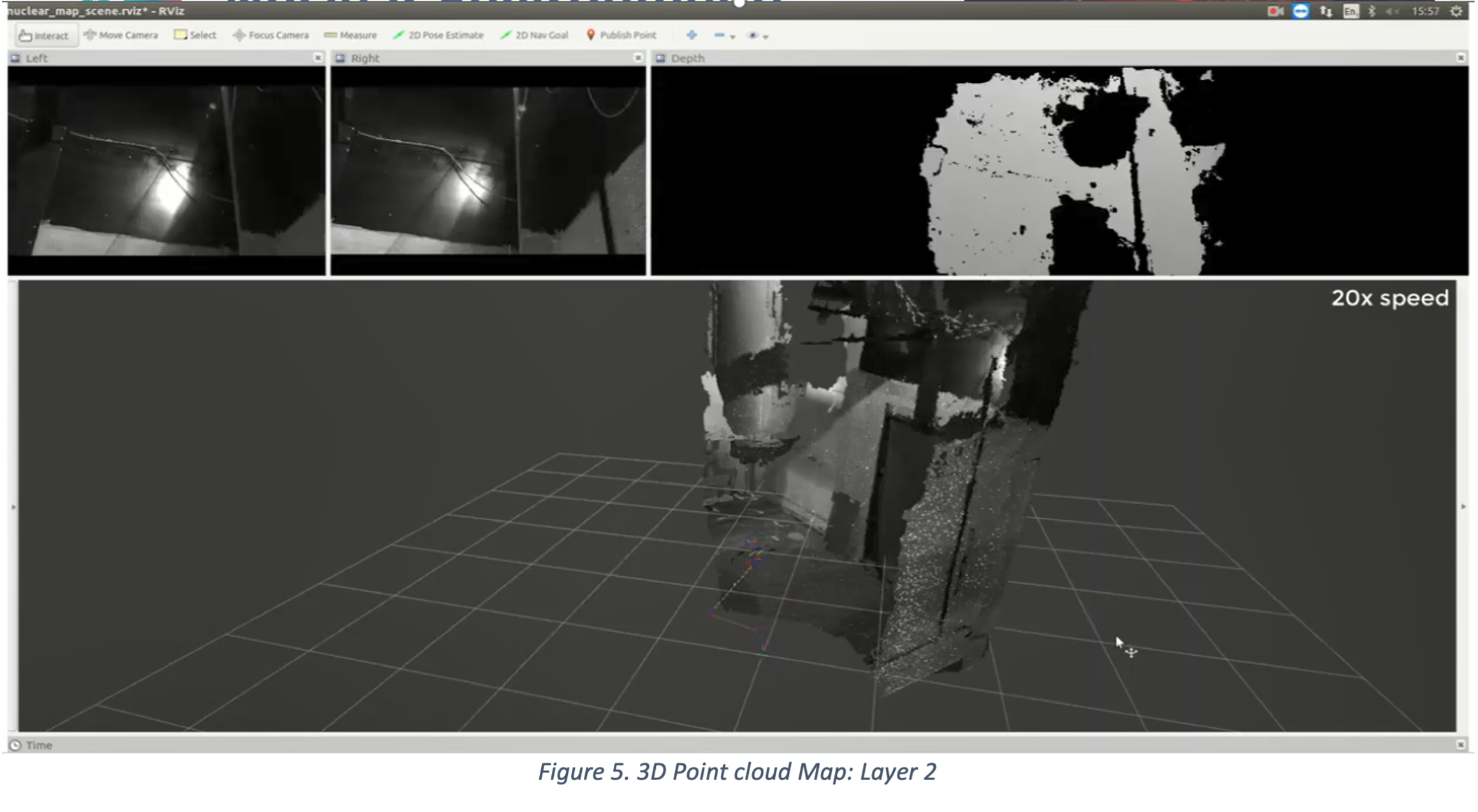

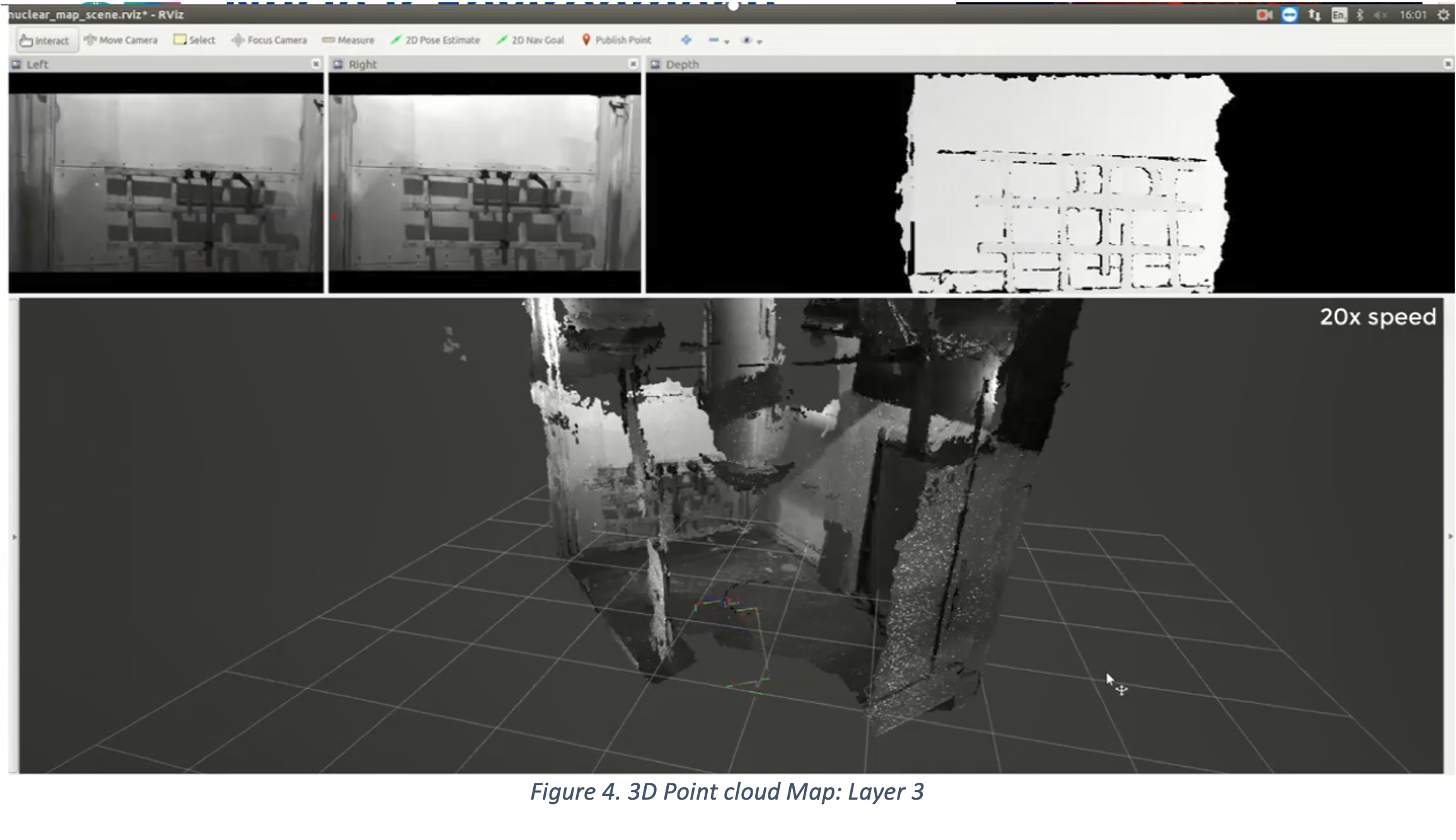

The initial ThORP cell mapping trials were conducted by lowering the robot-mounted Phobos through the ceiling of a test cell at NNL. The robot rotated the Phobos 3D camera horizontally and then incrementally lowered vertically to produce a complete 3D point cloud of the nuclear cell. In this demonstration, the system was equipped with a spectrometer from IS-Instruments to characterise the cell’s contents chemically.

The images below demonstrate the entire, completed 3D map of the nuclear cell.

The demonstration was expanded to include the full roving robot vehicle (RoV) to provide a comprehensive technology demonstrator for nuclear decommissioning.

John Brotherhood, Jacobs, Project Technical Lead, commented:

“I think the best moment in the project was during the demonstration week, when we demonstrated some of the novel concepts…, as part of the toolkit approach to decommissioning. This showed how decommissioning of nuclear facilities could change. The collaborative element of the project was essential to us and the different technologies we could bring to bear on the decommissioning challenge.”