Project Description

Client Challenge: Concrete Section Inspection

The client wanted to increase the use of automation and robotics to improve the installation and monitoring of the life of large pre-cast concrete (PCC) sections, bringing about a series of technology developments from i3D robotics.

Originally, i3Dr developed tunnel mapping sensors to detect water ingress. i3Dr then developed hyper-accurate 3D vision systems to enable crack detection. This R&D was based on a desire to improve accuracy over traditional laser-based measurement technology.

Technology Development:

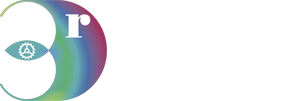

i3Dr works with the UK client base in the civil engineering sector and large-scale site owners. Using technology i3Dr developed for service cover condition monitoring for a UK port operator, i3Dr further developed both hardware and software to enable condition monitoring for the service cover lintel, asphalt and concrete.

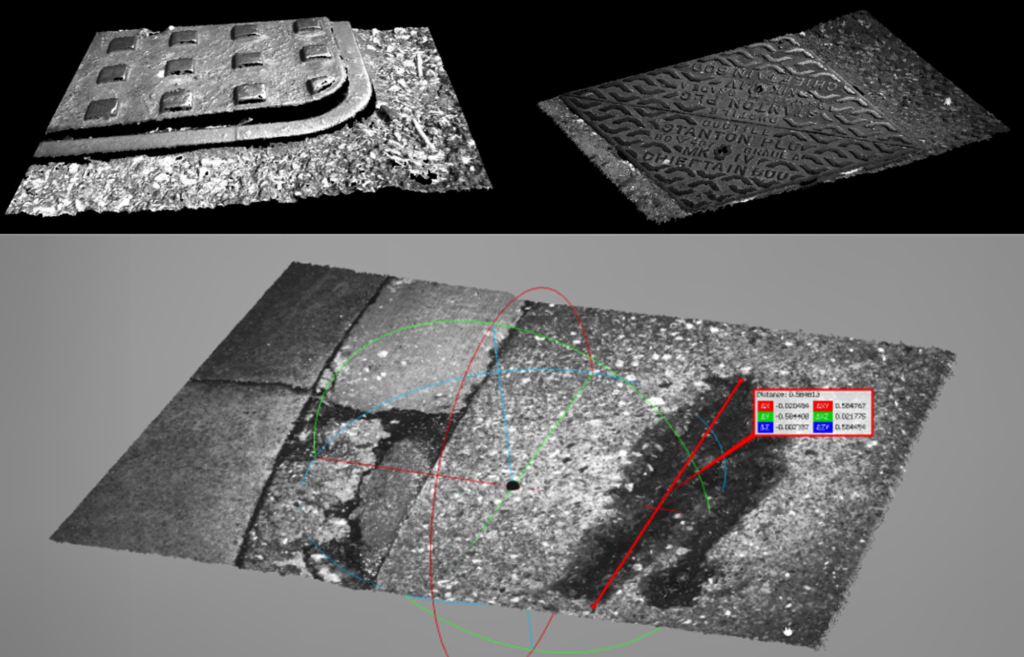

An increasing requirement has been to improve the measurement accuracy of “as installed” concrete to enable more detailed construction management (BIM) and move towards a digital, Industry 4.0 methodology for construction. To enable robots and automation systems to work accurately with installed pre-cast concrete, a series of innovations have been developed by the team at i3Dr.

i3Dr has used Phobos and Titania 3D cameras to enable robots to accurately locate and install fittings using hole location, based on machine learning software they created. The software automatically detects the hole position and gives a six-degree-of-freedom measurement to drive the robot end effector position.

Further developments from i3Dr have now enabled large-scale 3D mapping of assembled pre-cast concrete structures such as ventilation shafts.

Outcome:

i3D robotics has developed 3D inspection and measurement technology, software with advanced learning methodologies to support the use of robotics and autonomous systems when working with pre-cast concrete structures.