Case Studies

“We cannot solve our problems using the same thinking we used when we created them.” ~ Albert Einstein

There are many challenges facing the world today that require innovation to overcome.

These case studies highlight some of the projects we’ve been involved with, leveraging our stereo vision systems and machine learning algorithms to address challenges within Nuclear Decommissioning, Process Manufacturing, Construction, Medical, Autonomous Systems, Additive Manufacturing (AM), and more, each with a view to making these sectors more efficient, more accessible, less expensive, less wasteful, and less energy intensive.

A key driver for i3D is to assist existing industries in adopting technologies enabling them to streamline their processes. With the intelligent application of such technologies as 3D imaging, machine learning, artificial intelligence, virtual reality and augmented reality, it is possible to achieve net-zero targets. We are committed to playing our part in this crucial endeavour. Replacing traditional visual inspection methods within manufacturing sectors with stereo vision technology and machine learning will result in the in-process detection of defects within materials. In extreme environments, integrated robotics using remote sensing and imaging equipment will remove human operators from the scene, reducing the opportunity for harm and increasing safety levels. Autonomous systems integrated with AM will speed up construction and reduce costs. Stereo vision cameras integrated with AR, VR, and AI will revolutionise Medicine, how medical staff are trained and even how patients are assessed and treated.

Pre-cast Concrete Segment Inspection

Client Challenge: Concrete Section Inspection The client wanted to increase [...]

3D Mapping & Object Recognition in Radioactive Environments

i3D robotics has developed multiple inspection systems for decommissioning purposes [...]

IDEMA – Modular Housing Construction for Reduced Carbon-emissions

Traditional construction methods are labour-intensive, time-consuming, and contributes to the UK's carbon emissions. IDEMA sought to implement modular housing construction using pre-fabricated additive manufactured panels can significantly reduce the amount of time it takes to build housing, as well as reducing costs and carbon emissions.

Intelligent Robotic Inspection for Foundation Industry Optimisation (IRIFIO)

Manufacturing production optimisation for the Foundation Industries. Ceramics, Metals, Glass, Paper, Cement, and Bulk Chemicals, use manufacturing processes unchanged since the Industrial Revolution. They are responsible for 10% of the UK's total carbon emissions. The IRIFIO project involves developing intelligent vision systems to change that.

Stereo Theatre – Remote Surgery

Stereo vision camera systems are being integrated with sensors, AR, VR, and AI to create a 3D representation of a patient. This technology could eventually be used to train more surgeons through remote learning, as well as consulting with medics requiring specialist help operating in remote or dangerous locations.

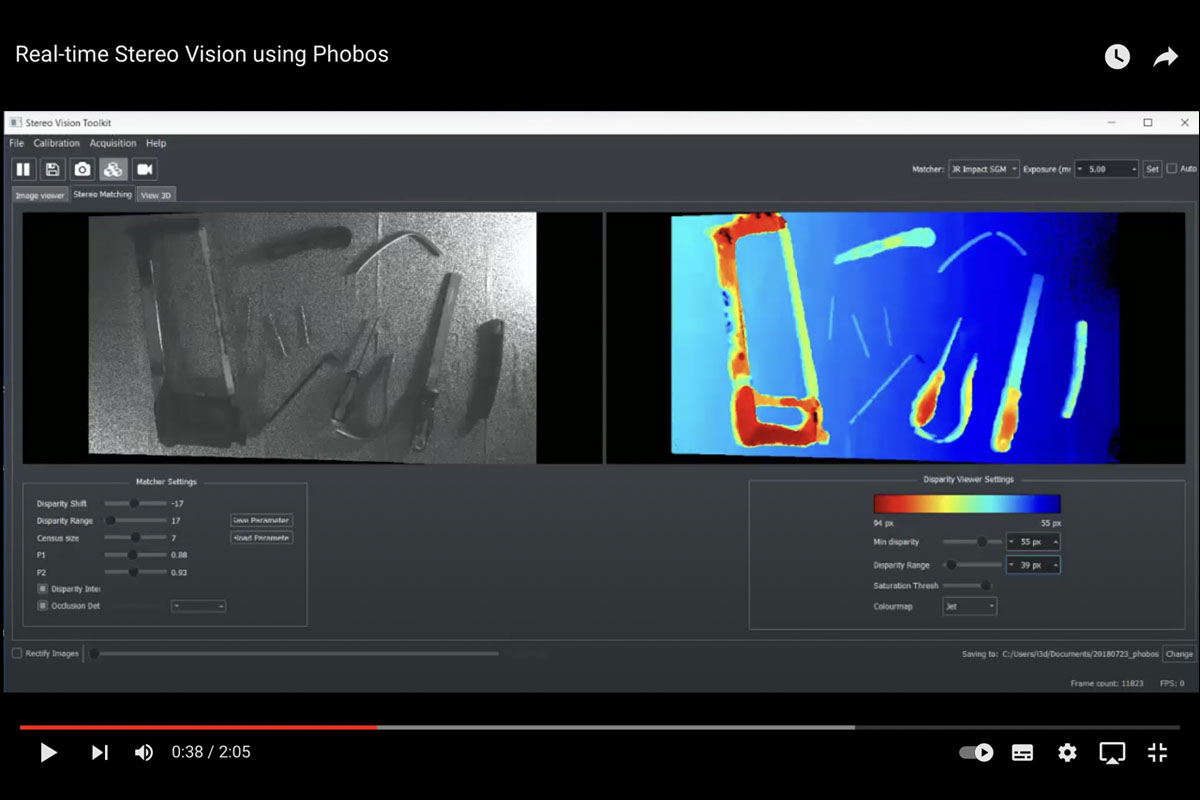

Identifying Unknown Sharps in Gloveboxes

Sellafield is home to around 350 nuclear gloveboxes in need of decommissioning, a process inherently dangerous to human operators. i3Dr has developed a stereo vision camera system capable of producing a 3D map of the interior of a glovebox, locating and identifying sharp objects and placing them in a point cloud.